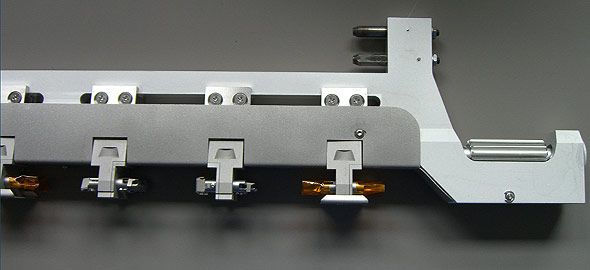

PVD racks (trees, shieldings, fixturings etc.) are to be cleaned off regularly. Today this takes place usually by simple but however abrasive sand blasting with following disadvantages:

- Damage of substrates by abrasive effects

- Blockades of turn tables during coating process by blasting particles released in bearings

- Timeconsuming and cost- inefficient

- Decoating of PVD furnitures by chemical vice versa provides lots of advantages:

- No impact on substrate or even abrasion effects

- No coatings by mistake due to blockades of turn tables

- Low cost in expenses and man power

The cleaning / decoating process itself for a complete set of racks with an average thickness of 100µm takes only 4-6 hours. So it doesn´t matter if only 1 kind of coating has been applied or as in almost all cases a variety of different coatings. The racks are ready for remount into PVD oven without any further cleaning step.

Cleaning off / decoating of racks and furnitures are not restricted to parts made of steel or stainless steel but can also consist of ceramic materials like Al2O3 or similar. Further examples regularly cleaned by ab solute Chemie GmbH:

- Masques and templates

- Solar modules

- ITO coatings